Mundorf MLytic Audio Grade MLGO Capacitors

Mundorf M-Lytic AG Audio Grade Power Capacitors - MLGO

The Mundorf MLytic AG Audio Grade Power Cap series is especially engineered for use in small power and pre-amplifiers. They are a snap-in capacitor and so particularly suitable for new builds, upgrades, repairs and modifications.

Great replacement for the now-defunct Black Gate capacitors.

8 Items In Total

Specifications MLGO (MLYTIC GLUE-ON):

- Long life span

- Compact size

- Temperature Range for 16V to 63V: -40°C/-40°F to +125°C/+255°F

- Temperature Range for 80V to 160V: -25°C/-13°F to +105°C/+220°F

- Max. Reverse Voltage: 2V

- Leakage Current (IL): ≤0.008 * CR (uF) * UR (V) + 6uA after 5 minutes at UR

- ESL: 20nH equivalent series inductance

- Certification: DIN 41332; IEC 60384-4; RoHS Compliant; REACH Compliant

- Made in Germany

- External Insulation: Lead free; PVC sleeve with end disk; voltage-proof ≥2500A

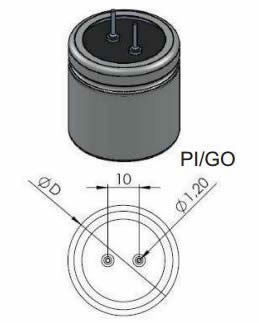

- Terminal Leads: Non-magnetic, straight, tinned copper wires 1.2mm x 10mm (Ø x L) - about AWG17

- Vibration-reducing, traction-relieving, self-adhesive MPSA mounting pad.

Mundorf Audio Grade Power Cap Size.

Technical Information:

MLytic Power Capacitors have a whole range of special features, all of which serve one purpose: the most authentic music playback possible. A basic requirement for achieving this aim is to minimise the undesired losses (ESR) and inductivities (ESL) occurring in the capacitor that impact negatively on the original signal. The use of high-purity materials for the anode foil and the highest production precision ensures a homogeneous etching structure of the crystalline Al2O3 layer. They use a special, titanium-coated cathode foil allows capacitors with unusually low ESR values.

Between these two foils we combine highly flowable, chloride-free and largely water-free long-life electrolytes with extremely soft special paper (mostly abaca-esparto paper) that is characterised by high mechanical stability, outstanding internal damping and electrolyte absorption capacity. Moreover, we do not use magnetisable, inflexible, poorly conducting steel for the connectors (global snap-in standard); instead, we exclusively use highly conductive tin-plated copper wires for the highest currents.